The benefits of specifiers engaging with insulation manufacturers

Our technical services department has been contacted, on multiple projects, about there being insufficient depth in the floor build-up to accommodate the insulation for the required ground floor U-value. Sometimes the thickness of extruded polystyrene (XPS) needed was around double the depth of the insulation zone allowed for.

This particular issue with ground floor constructions has been a common feature of technical enquiries lately. At face value it might seem like a relatively minor problem that should have a simple resolution – but what if it shouldn’t be dismissed so easily? And what if what it says about the ways in which specifiers and insulation manufacturers could help deliver better-performing buildings is, in fact, illuminating?.

This is not a problem unique to XPS. The qualities that make XPS a good all-round insulation solution mean it is not the best-performing in terms of thermal efficiency. But, in the majority of cases, no commonly available insulation material is capable of performing well enough. People want insulation to achieve the impossible.

Getting U-value calculations right and having accurate material data in them is fundamental to good construction practice. It shows that all parties involved – from specifier, to Building Control Body, to contractor – understand the build-ups being specified and installed, and the importance of the outcomes being aimed for.

Though most U-value calculations carried out are accurate and fit for purpose, when we do see inaccuracies, they tend to be glaring and concerning. Hoping to achieve the desired U-value with very limited space risks the specification of an insulant on thermal efficiency alone – without assessing whether its other qualities are suitable to meet the performance requirements for the intended application.

We have in the past received technical enquiries where PIR insulation was specified, only to realise the additional load-bearing capability offered by XPS was needed. Because of the slight difference in thermal performance, the consequence is they don’t have a deep enough insulation zone.

The project then faces the possibility of a compromise: meet the required U-value but risk having insufficient loadbearing capability; or have the right compressive strength but risk non-compliance in terms of energy efficiency.

If we see inaccuracies in a U-value calculation or specification, it is often at a very late stage. Because specifications have been set – and, in the case of floors, the ground possibly even dug out already – our advice means an inconvenient change to the project.

When we flag something, we are more likely to be seen as the ‘difficult’ party. We then must go the extra mile to explain the reason for our concern. That approach is backwards, and our industry needs to do better at pursuing accuracy and questioning whether something is too good to be true.

Whatever the building size, the principle is the same: speak to us early in the project timeline if you can. Nobody knows an insulation product better than the manufacturer themselves. Preparing information about U-value targets, performance requirements and outline specifications helps to reduce the likelihood of shocks or inconvenience later.

Correct specification and calculations are one thing, but thermal insulation only performs as well as it is installed. The best specified floor, wall or roof means nothing if what happens on site does not correlate with what was designed.

Nobody reading this will be a stranger to errors in installation that are either picked up too late or have been covered up and made unavailable for inspection, left unaddressed.

Closing the performance gap (that is, getting buildings to perform in-use as they are predicted to perform on paper) requires time and attention to detail. This can be in short supply on construction projects. That is not to be negative about our industry; it is a reflection of enquiries that come across our technical helpdesk every week.

Construction product manufacturers, including those producing insulation, are keen to make their solutions easy to work with. So why do issues occur?

Insulation is only likely to form part of a warrantied system (and be subject to on-site checks and extra manufacturer support) on larger projects. The rest of the time the manufacturer basically loses control over how their product is used once it leaves the factory gate.

Installation instructions are, by necessity, generic and cannot cover every possible scenario. In addition, installing products on site means working in 3D, and 2D details can’t always show what is needed. All manufacturers offer technical support, but that resource or advice won’t be accessed if an installer doesn’t want to seek it out. If they don’t know (or, worse, don’t care) that they might be doing something wrong, then they simply won’t ask.

How feasible is it to foresee what an installer might do? And how reasonable is it to try to foresee those things? Imagining and then planning for every way that an installer could get things wrong is time consuming and ultimately impractical.

It is good practice to consider buildability when specifying and detailing. Simpler build-ups go a long way to making for simpler installation, especially when making a design on paper reality on site. To aid that approach, specifiers can again engage with manufacturers to guide decision-making that guards against some ‘what if’ scenarios.

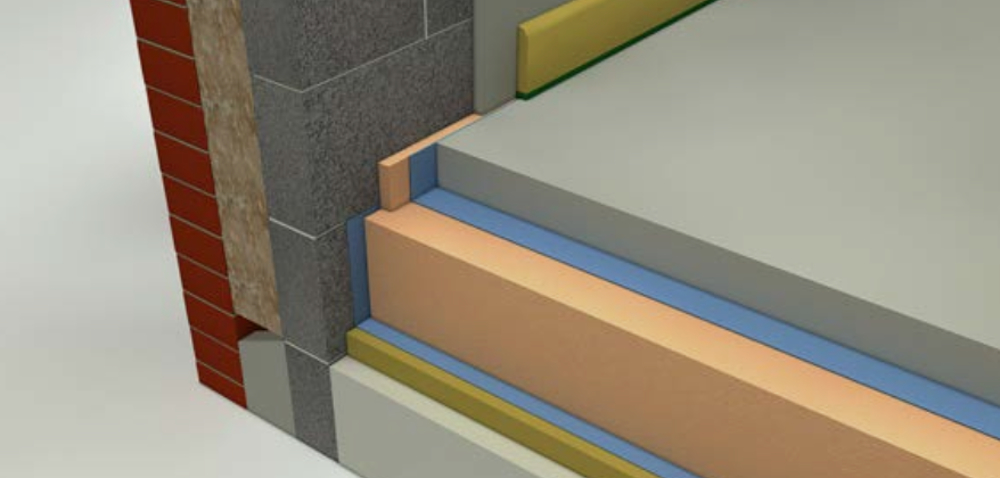

Consider a common example with ground floor constructions. Foil-faced insulation products, like PIR boards, must be laid above the damp proof membrane (DPM) and below the air and vapour control layer (AVCL). If they are allowed to come into contact with the ground, moisture or curing concrete or screed then the foil face can become damaged and reduce the performance of the insulation.

There are two main issues here. The first is that our technical team has encountered many projects where they have been asked whether it is okay that a PIR board was installed in the wrong position. The second is that, even if a problem is identified, there is a lack of appetite to take up the floor to ensure it is re-laid correctly. Both these issues assume the problem is identified in the first place.

Extruded polystyrene can be installed in the same way: above the DPM and below the AVCL. But thanks to its low moisture absorption, it can also be installed below the DPM without any fear of losing performance. The DPM can therefore act as the AVCL as well, thus saving money on a second membrane layer while also guarding against potentially incorrect installation.

This kind of value is what manufacturers can bring to the specification process, with a view to supporting installers once a project reaches site. It shows that the thinnest insulation does not necessarily represent the best overall value. It can be worth exploring alternative solutions and seeking manufacturer advice on the possible installation benefits.

Compared to simply having the lowest lambda value, another material might create savings in material and labour, helping to ensure the building delivers its intended performance once constructed.

The article appears in the AT journal issue 153, Spring 2025 as " The benefits of specifiers engaging with insulation manufacturers" ans was written by Rob Firman, Technical and Specification Manager, Polyfoam XPS.

--CIAT

[edit] Related articles on Designing Buildings

- Accredited construction details ACDs.

- Beam and block.

- Beam and Polystyrene Block Suspended Flooring - Case Study.

- BREEAM Insulation.

- Cavity wall insulation.

- Condensation.

- Conduction.

- Cork flooring.

- Domestic floors: Part 1: Construction, insulation and damp proofing.

- Floor insulation.

- Ground level.

- Heat transfer.

- Insulation for ground floors.

- Passivehaus Foundation Insulation - Case Study.

- Resilient flooring.

- Rubber flooring.

- Solid wall insulation.

- Suspended timber floor.

- Thermal bridge.

- Thermal insulation for buildings.

- Types of floor.

- Types of flooring.

- Types of insulation.

- U-value.

Featured articles and news

Managing building safety risks

Across an existing residential portfolio, a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.